A productive, reliable system thanks to good uptime ( MTBF) and low average repair times (10 minutes)

Highly efficient use of utilities enables a low operating cost and a good environmental performance

Filling Capacity

|

5000-6000 box/hr

|

Filling Range

|

125ml, 200ml, 250ml, 500ml, 1L

|

|

Packaging Shape

|

Slim Shaped, Standard Shaped

|

Shelf Life

|

in 25-30oc , juice shelf life 6-12months , milk 6 months

|

Packaging Material

|

PET/PAPER/PE/AL/PE/PE

|

Voltage

|

220V/380V 50Hz

|

Power

|

35kw

|

Air Consumption

|

Air pressure: ≡0.6 Mpa

|

Weight

|

1500kg

|

Size

|

3000*2500*3500mm

|

Manufacture and Model:

1) PLC: Japan mitsubishi

2) Touch Screen: Japan mitsubishi

3) Motor: Domestic

4) Temperature control: Real da

5) Inverter: Japan mitsubishi

6) Power:380V;50Hz

7) Low-voltage electrical apparatus: Omron

8) Pneumatic components: Air TAC

9) Proximity switch: Japan & omron

10) Photoelectric: Japan

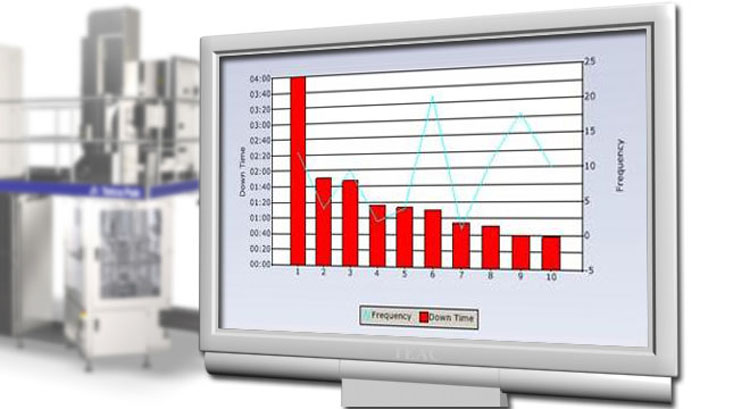

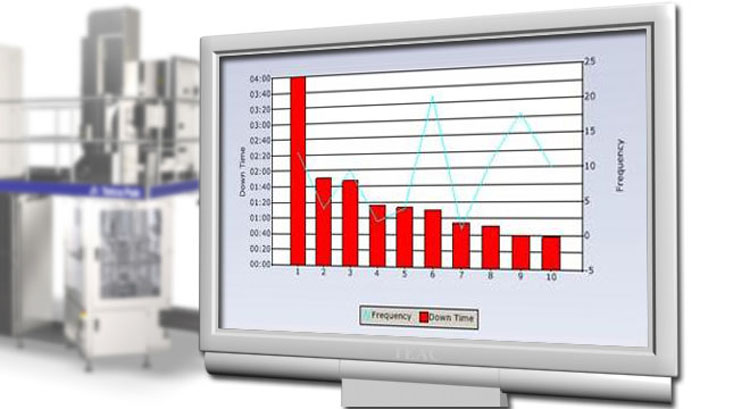

PLMS Centre

Operational control and performance analysis

The packaging line monitoring system (PLMS) enables tracking of production performance, such as possible stop reasons, efficiencies, waste levels.

Operator panel

It*s never been easier to operate

The production is easily managed through a Tetra Pak Operator Panel (TPOP) system on the ground level. All major functions can be initiated and supervised - from production preparation to the Cleaning in Place (CIP) function.

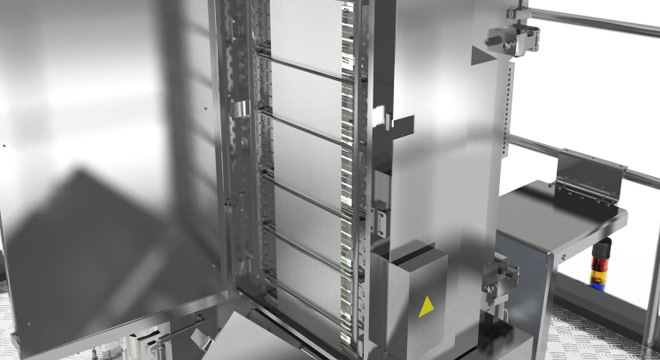

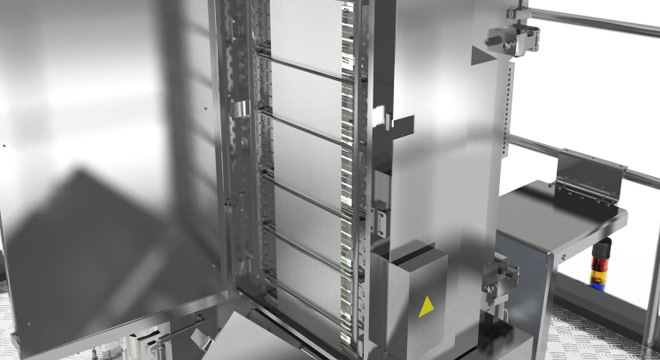

Aseptic system

For reliable sterilisation of packaging material

Consists of a shallow hydrogen peroxide bath, squeegee rollers and a heating chamber. Rollers distribute the hydrogen peroxide evenly; controlled heating and evaporation give effective sterilisation. Control of aseptic parameters ensures product protection and minimises the risk of operator errors.

Leave a Reply