Functions and Features:

1) The machine is suitable for filling milk, juice, soymilk etc other beverage.

2) The machine Automatic Form Feed 每sterilize 每filling 每shaping 每 sealing

3) PLC human control, Human - Machine Interface with English and Chinese display. Intuitive operation and Low Fault rate.

Filling Capacity

|

2000-2400 box/hr

|

Filling Range

|

125ml, 200ml, 250ml, 500ml, 1L

|

Packaging Shape

|

Slim Shaped, Standard Shaped

|

Shelf Life

|

in 25-30oc , juice shelf life 6-12months , milk 6 months

|

Packaging Material

|

PET/PAPER/PE/AL/PE/PE

|

Voltage

|

220V/380V 50Hz

|

Power

|

5kw

|

Air Consumption

|

0.4-0.8m3/min 1.0Mpa

|

Weight

|

1800kg

|

Size

|

4000X1900X3500mm

|

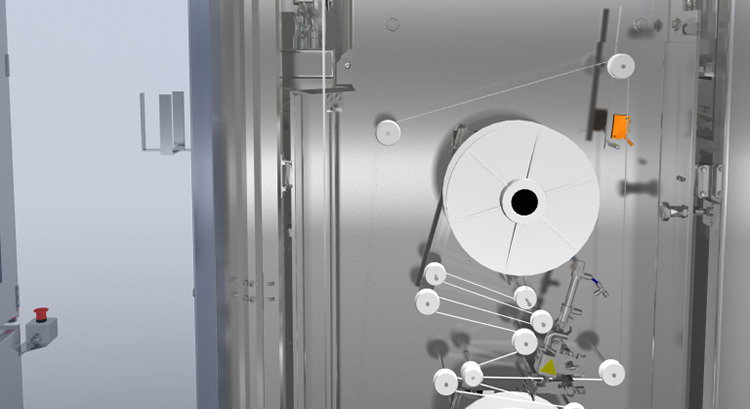

Automatic Strip Splicing

Quality splicing

Enables correct, repeatable splicing of longitudinal strip reels, and at the same time makes the operation less labour intensive.

Operator panel

It*s never been easier to operate

The production is easily managed through a Tetra Pak Operator Panel (TPOP) system on the ground level. All major functions can be initiated and supervised - from production preparation to the Cleaning in Place (CIP) function.

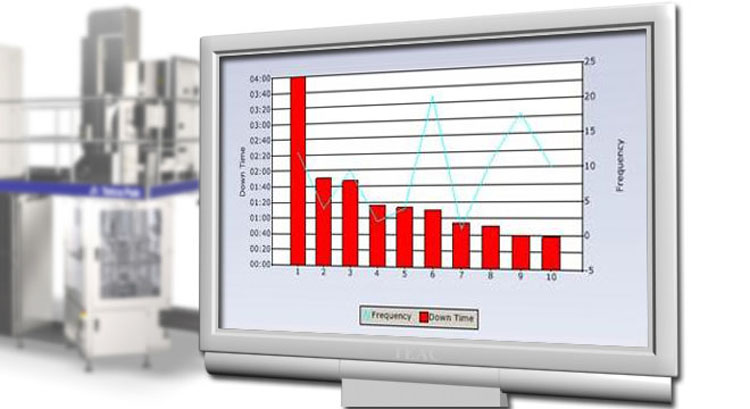

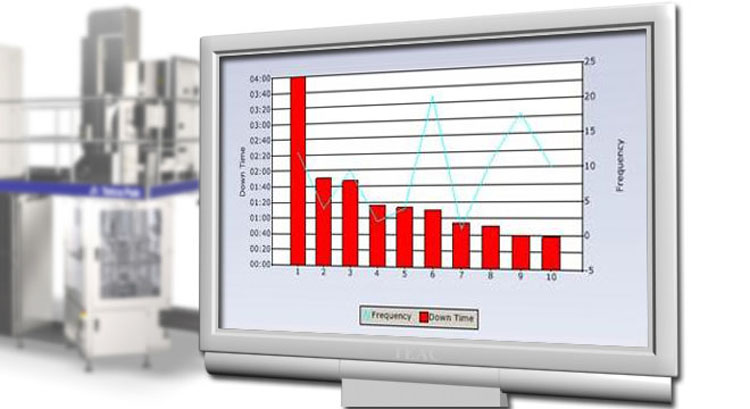

PLMS Centre

Operational control and performance analysis

The packaging line monitoring system (PLMS) enables tracking of production performance, such as possible stop reasons, efficiencies, waste levels.

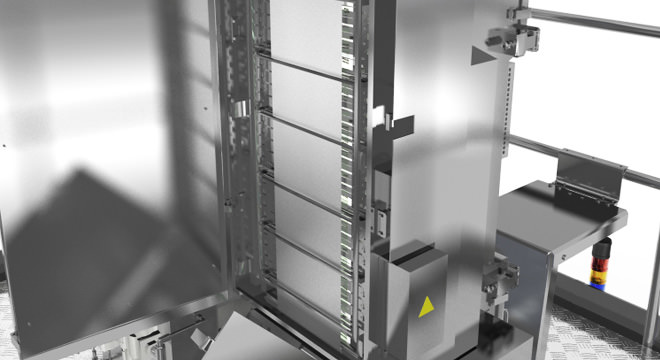

Packaging material in-feed

Long production runs raise efficiency

Each Tetra Pak unit holds a jumbo reel of packaging material with sufficient supply for almost fifteen hours of production at the higher speed, and about eighteen hours at the lower speed. A jumbo reel holds sufficient material for up to 36,000 packages.

Fully automatic splicing unit

Neat seal between reels

The splicing unit heats and pressurises the packaging material to automatically make a neat seal between one reel and the next, so package production can continue uninterrupted.

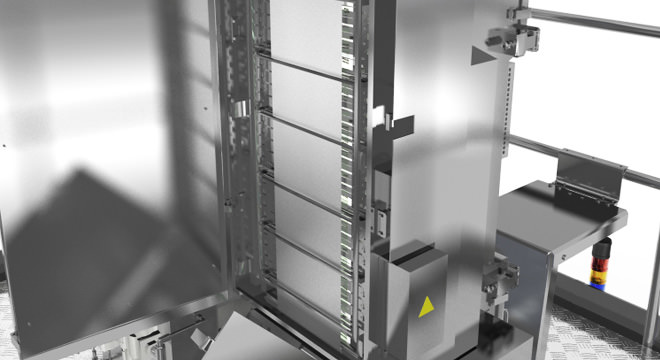

Aseptic system

For reliable sterilisation of packaging material

Consists of a shallow hydrogen peroxide bath, squeegee rollers and a heating chamber. Rollers distribute the hydrogen peroxide evenly; controlled heating and evaporation give effective sterilisation. Control of aseptic parameters ensures product protection and minimises the risk of operator errors.

Leave a Reply