- HOME

- PRODUCT

- Aseptic Tetra Pak Filling Machine

- Aseptic Brick Type Filling Machine

- Aseptic Carton Box Filling Machine

- Diamand Packaging Filling Machine

- Automatic Spout Pouch Filling Machine

- Small Automatic Doypack Filling Machine

- High Speed Stand Up Pouch Filling Machine

- Plastic Bottle Blowing Machine

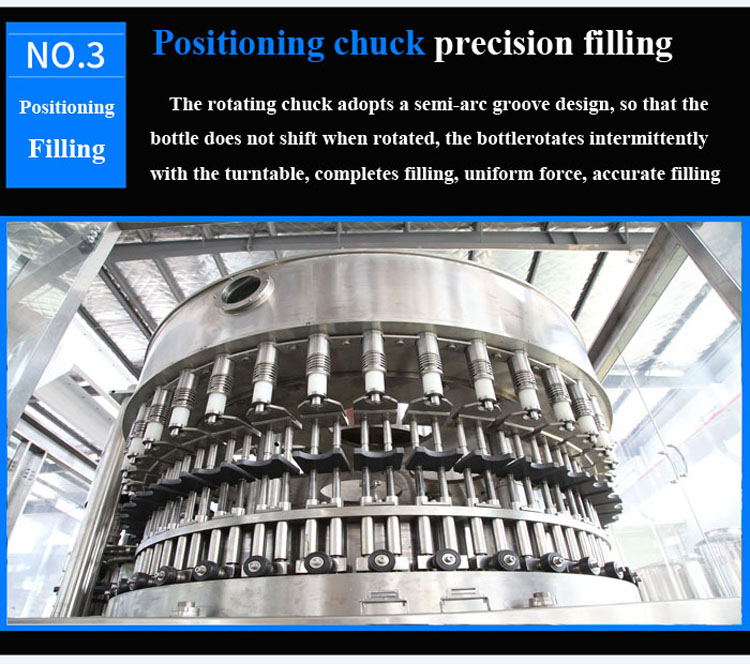

- Plastic Bottle Filling Machine

- Linear Filling Sealing and Capping Machine

- Ice Lolly Filling Sealing Machine

- Inflatable Bag Filling Machine

- Small Filling Machine

- Oil / Wine Filling Machine

- ABOUT

- VIDEO

- NEWS

- CONTACT

- SHEAN GROUP

Leave a Reply